The complete bill of materials needed for the whole model is here.

The assembly guide shows, how to make following things:

- Frame

- Pendulum segment

- Motor segment

- FPGA shield

Frame

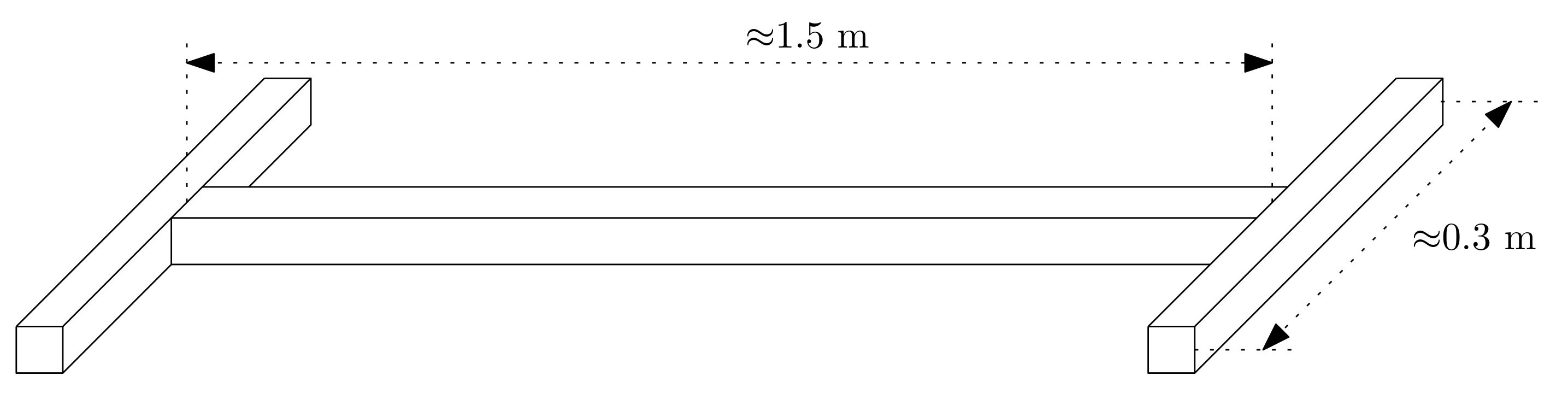

The frame is constructed from three aluminum profiles 40x40, 8 mm slot I-TYPE. The configuration and recommended lengths for 20 pendulums with two motors are depicted in the following figure:

Pendulum segment

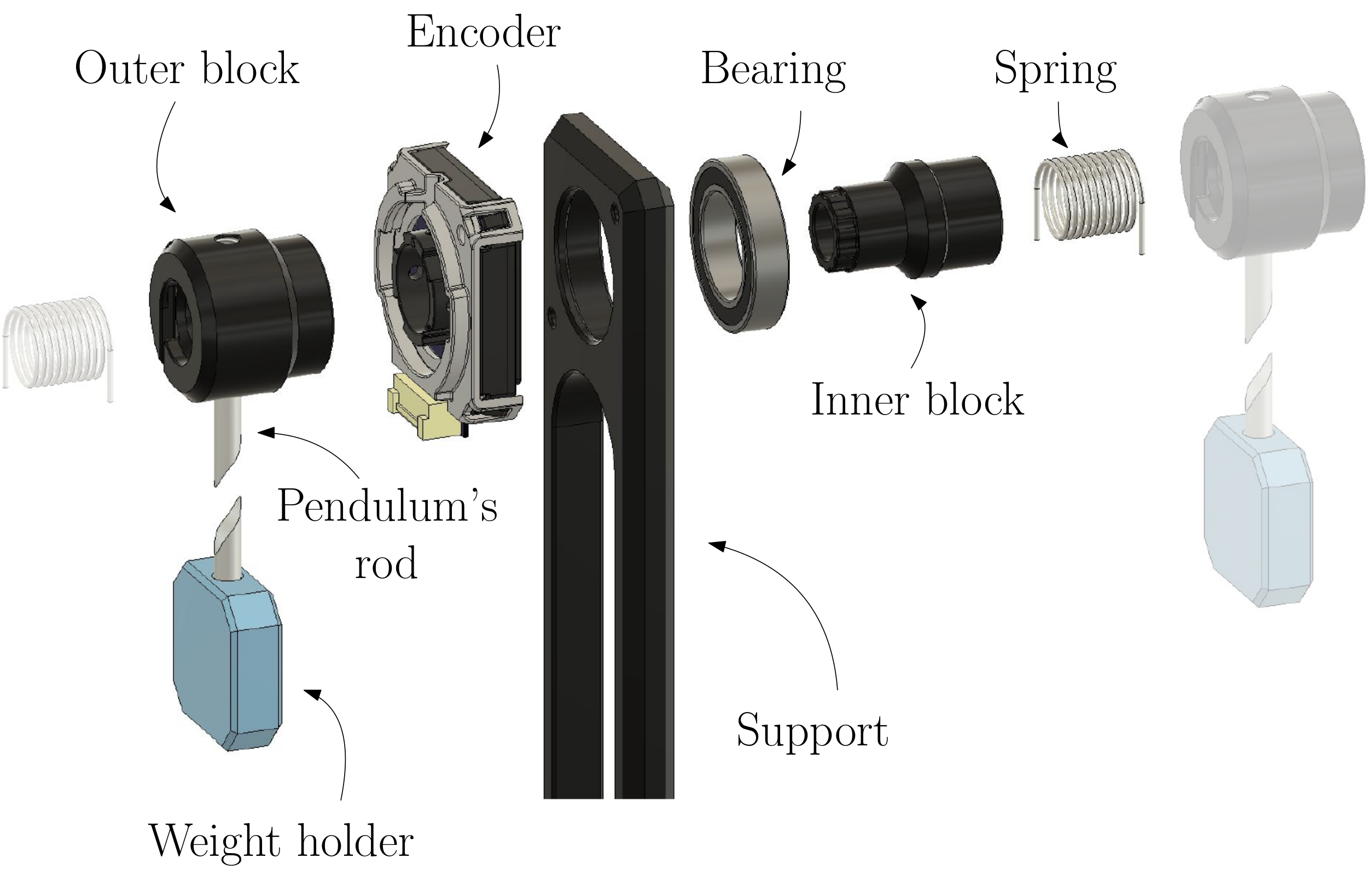

The pendulum segment is designed as a combination of off-the-shelf and 3D-printed components.

Requirements

- Spring

- Bearing

- Pendulum’s Support

- Pendulum’s rod

- Rotary encoder

- Pendulum’s block

- Inner block

- Outer block

- Weight holder

- Screws

- M3x14 hex socket button head screw (Qty.: at least 2x)

- M6x16 hex socket cap screw (Qty.: 1)

Instructions

-

The configuration of the pendulum segment is here: https://a360.co/3uP4RIG.

- Insert the bearing into the support

- Insert the inner block into the bearing

- Attach the encoder to support using 2 diagonally placed screws or all 4 screws (M3x14)

- Place the outer block onto the inner block and the encoder

- Insert pendulum’s rod with weight holder into the outer block

- Secure weight holder with a small screw if necessary.

- Insert the spring into the outer/inner block

- Attach the support to the frame with M6x16.

Encoder cable

Requirements

- 4-wire cable

- Length of the segment: from 40 cm to 1 m.

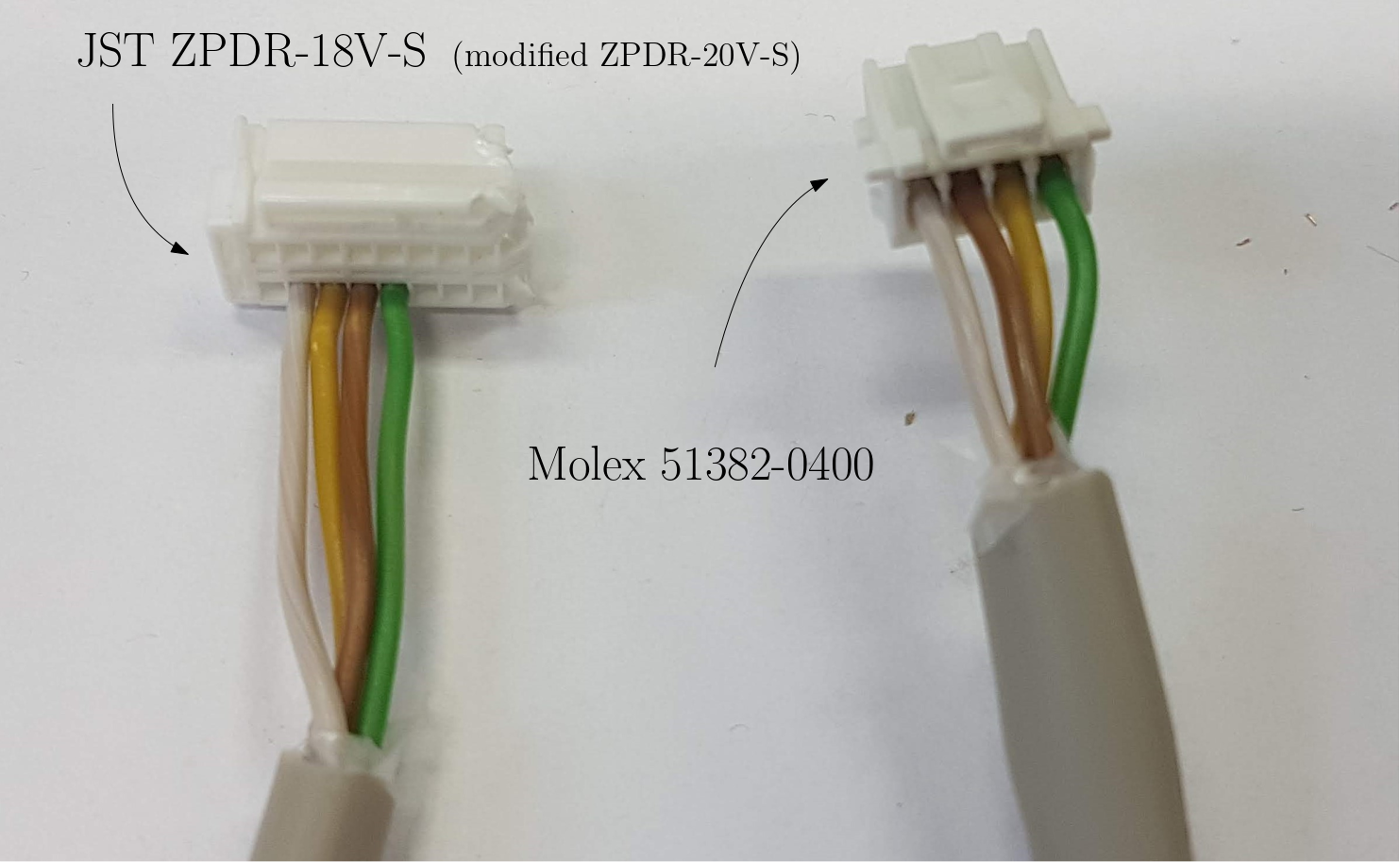

- Connector JST ZPDR-18V-S with 4 contacts SZPD-002T-P0.3

- Connector Molex 55935-0410 with 4 contacts Molex 56134-9001

- Crimping tool (recommended: PAD-11 ENGINEER)

Instructions

- Get desired length of the cable from the encoder to the FPGA Shield. Note, that the cable could be inserted into the support.

- On both sides, crimp the conductors and insert them into the connectors.

- For the JST ZPDR-18V-S, use the contact SZPD-002T-P0.3

- For the Molex 55935-0410 use the contact Molex 56134-9001

- See picture below of the desired cable configuration. Note, that because the JST ZPDR-18V-S was not available at the time of the assembly, we had to buy JST ZPDR-20V-S and cut off a part of the connector.

- Note, that the order of colors is not the same on both connectors.

Motor segment

Requirements

- NEMA17 1.8° stepper motor

- 3D-printed motor support: https://a360.co/3M9fMnV

- 3D-printed connecting block

- Motor Driver (Pololu Tic T249)

- Screws

- M3x14 hex socket button head screw (Qty.: at least 2x)

- M6x16 hex socket cap screw (Qty.: 1)

- USB-B cable for connecting motor driver to PC.

FPGA shield

Requirements

- DE0-Nano FPGA Board

- Custom-made PCB; see: https://github.com/ptrbroz/AA4CC_FK_model_sensors/tree/main/FK_fpga_shield

- Electrical components listed in the bill of materials.